-

WITH A PRECISION ENGINEERED DUAL BEARING MOTOR, AND A MACHINED ALL BILLET ALUMINUM HOUSING, THE OCTAGON DIRECT DRIVE ROTARY MACHINE IS SPECIFICALLY DESIGNED TO ENHANCE THE NOMI GRIP SYSTEM’S UNIQUELY INNOVATIVE FUNCTION. COMBINED WITH THE NOMI GRIP, Z-AXIS PIN, AND CUSTOMIZED NOMI NEEDLES, THE LATEST MOST TECHNOLOGICALLY INNOVATIVE METHOD FOR THE DELIVERY OF PIGMENT INTO THE SKIN IS NOW AVAILABLE. THOUGH THE SPECIFIC ENGINEERING OF THIS MACHINE’S MOTOR MAKES IT AN ESSENTIAL PART OF THE NOMI GRIP MASTER SYSTEM, THE MACHINE MAINTAINS A VERSATILITY THAT ALLOWS FOR VARIOUS APPLICATIONS AND DESIRED RESULTS. https://www.youtube.com/watch?v=aTJJAqhVTRI

-

THIS CNC MACHINED SINGLE PIECE TUBE-GRIP IS METICULOUSLY DEIGNED TO HOUSE A UNIQUE CYLINDRICAL Z-AXIS PIN. FOR THE SOLE PUPOSE OF CHANGING WHAT IS UNDERSTOOD TO BE THE STANDARD OR CORRECT MOTION OF THE NEEDLE BAR, AND THEN ALTERING THE DIRECTION OF THE NEEDLE BARS MOVEMENT TO ACHIEVE AN ENHANCED RESULT. THE PATENT PENDING DESIGN OF THIS GRIP AND ALL OF ITS INTERACTING PARTS IS WHAT WE BELIEVE SHOULD BE A WELCOME INNOVATIVE CHANGE TO AN UNEXPLORED SIDE OF MECHANICALLY IMPREGNATING THE SKIN WITH INK. MACHINED OUT OF HIGH QUALITY ALUMINUM AND TREATED WITH A PROPRIETARY HARD COAT ANODIZING PROCESS, THIS GRIP WILL WITHSTAND ALL MEDICAL INDUSTRY STANDARD AUTOCLAVE PROCEDURES. THE NOMI GRIP, AND NOMI NEEDLES CAN BE PURCHASED SEPARATELY, AND WILL FUNCTION WITHIN ITS INTENDED USE WITH MOST DIRECT DRIVE ROTARY MACHINES WITH AN OFF-SET CAM. NOTE: TEKORI NOMI NEEDLES ARE SPECIFICALLY ENGINEERED TO ENHANCE THE NOMI GRIP TATTOO SYSTEM'S RESULTS. WITH HIGH QUALITY #15 MEDIUM TAPER STAINLESS STEEL PINS, ASSEMBLED IN AN OFF SET FLAT MAGNUM CONFIGURATION. THESE INNOVATIVE NEEDLE SETUPS ARE AN ESSENTIAL PART OF THE SYSTEM'S SUCCESS. https://www.youtube.com/watch?v=Zy1DWfm94-U

-

THE NOMI NEEDLES IN THIS BOX ARE SPECIFICALLY ENGINEERED TO INTERACT WITH THE NOMI GRIP AND THE Z-AXIS PIN, TO ENHANCE THE NOMI GRIP SYSTEM’S RESULTS. WITH HIGH QUALITY #15 MEDIUM TAPER STAINLESS STEEL PINS, ASSEMBLED IN AN OFF SET FLAT MAGNUM CONFIGURATION. THESE INNOVATIVE NEEDLE SETUPS ARE AN ESSENTIAL PART OF THE NOMI GRIP SYSTEM’S SUCCESS. THE NOMI NEEDLES, AND NOMI GRIP CAN BE PURCHASED SEPARATELY, AND WILL FUNCTION WITHIN ITS INTENDED USE WITH MOST DIRECT DRIVE ROTARY MACHINES WITH AN OFF-SET CAM. THESE NEEDLES CAN NOT FUNCTION WITHIN THERE INTENDED USE WITH ANY OTHER CONVENTIONAL TATTOO MACHINE, OR TUBE GRIP SET-UP OTHER THAN WHAT IS DESCRIBED ABOVE. https://www.youtube.com/watch?v=ylYSz_YJZ4Q

-

WITH THE OCTAGON DIRECT DRIVE ROTARY MACHINE, METICULOUSLY ENGINEERED NOMI GRIPS, ADJUSTABLE Z-AXIS PIN, AND CUSTOM DESIGNED NOMI NEEDLES,THE NOMI GRIP MASTER SYSTEM PROVIDES EVERYTHING NEEDED TO BEGIN ELEVATING YOUR TATTOOING. THIS IS A COMPLETE KIT, ALL NECESSARY PARTS OF THE SYSTEM ARE INCLUDED. INCLUDED:

- OCTAGON DIRECT DRIVE ROTARY MACHINE

- 3 NOMI GRIPS

- 20 Z-AXIS PINS

- EXTRACTION TOOL

-

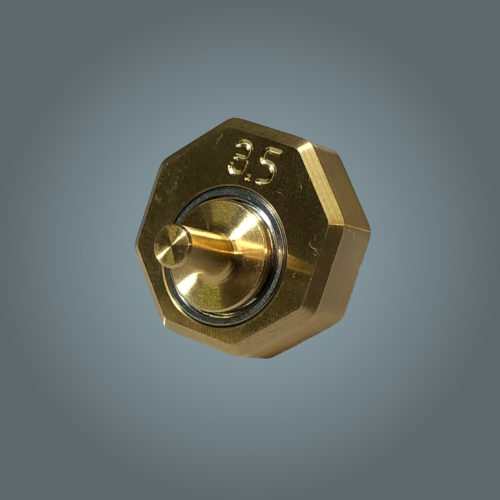

The Z-Axis pin is the most critical part of the Nomi Grip set-up. By introducing a secondary axis to the traditional standard motion of the needle bar, its interaction is the key factor in the replication of the Hanebori technique. Without this pin, the Nomi Grip and Nomi Needle function no differently than your standard tattoo grip and needle set-up. This is a single use piece of equipment and must be discarded after use. These Pins are sold by the dozen, or by bags of 25 and 50.

-

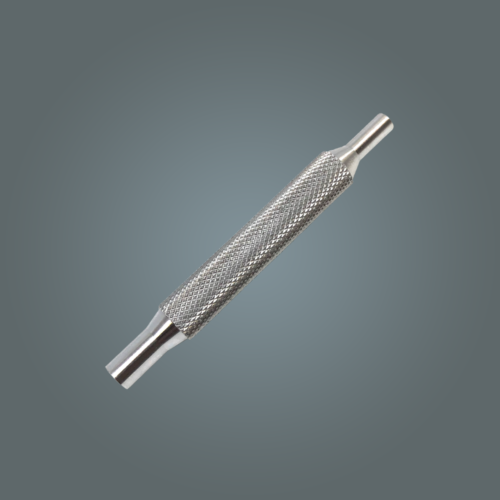

The Tekori Systems Nomi Grip Extraction Tool, is specifically designed to extract the Z-Axis Pin from the Nomi Grip. You can view the instructional video at tekorisystems.com/YouTube for a complete visual explanation of the purpose and function of this tool.

-

A tig welded low carbon steel frame with an oil blackened treatment, 1"x3/8"cores, six wrap 22 AWG hand wound coils, wrapped with burgundy gaff tape. A 22 μF capacitor, and 18 gauge front and back springs. This is a pre-tuned outliner that is set up to run at a speed of 115 CPS, @ 7 volts with a duty of 55% loaded. This machine will push both small and large needle groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs. https://youtu.be/GNsWiAb-R_A

-

Defiance Mfg. specializes in custom building a dependable everyday use tattoo machine personalized to each customers needs. You have chosen a Ductile Iron Coleman Widow style Combo frame with two liner geometry options, which includes six wrap 22 AWG hand wound coils with 1 1/8"x3/8"cores.The following three elements, frame style, geometry and coil size are a basic starting point to build off of. For instance six wrap 22 AWG coils, which is a standard coil size for an outliner, can be changed to a preferred coil size upon written request in the additional notes section. The rest of the following menu options listed below, are predominantly limited to aesthetics only. They do not offer detailed specifications along the lines of mechanics, tuning, capacitor size, spring gauges, etc. For a truly custom tool to be built to your specifications, you must be available for a verbal discussion, or email correspondence with our in-house machine builder Prof. Incredulous. https://youtu.be/dJ3at2ggWOY ATTENTION: You must select one of each of the options below for your custom build order to be added to your cart.

-

Defiance Mfg. specializes in custom building a dependable everyday use tattoo machine personalized to each customers needs. You have chosen a Ductile Iron Rogers J-Frame Mini Smashback Stinger with liner geometry, which includes six wrap 22 AWG hand wound coils. The following three elements, frame style, geometry and coil size are a basic starting point to build off of. For instance six wrap 22 AWG coils, which is a standard coil size for an outliner, can be changed to a preferred coil size upon written request in the additional notes section. The rest of the following menu options listed below, are predominantly limited to aesthetics only. They do not offer detailed specifications along the lines of mechanics, tuning, capacitor size, spring gauges, etc. For a truly custom tool to be built to your specifications, you must be available for a verbal discussion, or email correspondence with our in-house machine builder Prof. Incredulous. https://www.youtube.com/watch?v=iHzsvm4sJxA&rel=0 ATTENTION: You must select one of each of the options below for your custom build order to be added to your cart.

-

Defiance Mfg. specializes in custom building a dependable everyday use tattoo machine personalized to each customers desired needs. You have chosen a Walker Style Combo frame with Liner geometry, which includes eight wrap 24 AWG hand wound coils. These three elements, frame style, geometry, and coil size are a basic starting point to build off of. For instance eight wrap 24 AWG coils, which is a standard coil size for a shader, can be changed to a preferred coil size upon written request in the additional notes section. The rest of the following menu options listed below, are predominantly limited to aesthetics only. They do not offer detailed specifications along the lines of mechanics, tuning, capacitor size, spring gauges, etc. For a truly custom tool to be built to your specifications, you must be available for a verbal discussion, or email correspondence with our in-house machine builder Professor Incredulous. ATTENTION: You must select one of each of the options below for your custom build order to be added to your cart.

-

Defiance Mfg. specializes in custom building a dependable everyday use tattoo machine personalized to each customers desired needs. You have chosen the Coleman Widow Style Combo frame with three different geometry configurations to choose from, which includes eight wrap 24 AWG hand wound coils. These three elements, frame style, geometry, and coil size are a basic starting point to build off of. For instance eight wrap 24 AWG coils, which is a standard coil size for a shader, can be changed to a preferred coil size upon written request in the additional notes section. The rest of the following menu options listed below, are predominantly limited to aesthetics only. They do not offer detailed specifications along the lines of mechanics, tuning, capacitor size, spring gauges, etc. For a truly custom tool to be built to your specifications, you must be available for a verbal discussion, or email correspondence with our in-house machine builder Professor Incredulous. https://youtu.be/dJ3at2ggWOY ATTENTION: You must select one of each of the options below for your custom build order to be added to your cart.