All the tattoo machines displayed in this section come pre-tuned to operate exactly how the machine is described to run, i.e. a fast or slower running liner, a traditional whip shader, fast or slow black and gray shader, etc. All pre-tuned machines are backed by a thirty day satisfaction guaranty, or your money back. If you prefer a custom tattoo machine built to your exact specifications, navigate to the Custom Tattoo Machine Build section of this website.

-

A Ductile Iron frame with black oxide treatment, seven wrap 22 AWG hand wound coils with pure iron cores, wrapped with tan gaff tape, a pure iron Armature bar, a 22 μF capacitor and custom cut springs. This is a versatile outliner tuned to run at a speed of 120 CPS, at 7.0 volts. A strong punchy outliner, with a long throw, good for all liner needle configurations. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order by navigating to the Custom Build section of this site and have a custom machine built to your specifications.

-

WITH A PRECISION ENGINEERED DUAL BEARING MOTOR, AND A MACHINED ALL BILLET ALUMINUM HOUSING, THE OCTAGON DIRECT DRIVE ROTARY MACHINE IS SPECIFICALLY DESIGNED TO ENHANCE THE NOMI GRIP SYSTEM’S UNIQUELY INNOVATIVE FUNCTION. COMBINED WITH THE NOMI GRIP, Z-AXIS PIN, AND CUSTOMIZED NOMI NEEDLES, THE LATEST MOST TECHNOLOGICALLY INNOVATIVE METHOD FOR THE DELIVERY OF PIGMENT INTO THE SKIN IS NOW AVAILABLE. THOUGH THE SPECIFIC ENGINEERING OF THIS MACHINE’S MOTOR MAKES IT AN ESSENTIAL PART OF THE NOMI GRIP MASTER SYSTEM, THE MACHINE MAINTAINS A VERSATILITY THAT ALLOWS FOR VARIOUS APPLICATIONS AND DESIRED RESULTS. https://www.youtube.com/watch?v=aTJJAqhVTRI

-

A brazed mint green powder coat frame, with eight wrap 24 AWG hand wound coils wrapped with champagne prism tape, a 47 μF capacitor with 18 gauge front and back springs. This is a versatile color packer tuned to run at a speed of 110 CPS, at 7.0 volts with a duty of 53% loaded. This machine has 1 1/4" full size coils with a lot of punch and a long stroke good for all groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs.

-

This is a ductile iron frame, with eight wrap 24 AWG hand wound coils covered with gold prism tape, a 22 μF capacitor with 18 gauge front and back springs. This is a strong, fast running liner tuned to run at a speed of 120 CPS, at 7.0 volts with a duty of 55% loaded. This machine is a full size liner with a lot of punch and a medium stroke good for all groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order by navigating to the Custom Build section of this site and have a custom machine built to your specifications. https://www.youtube.com/watch?v=iHzsvm4sJxA&rel=0

-

A brazed and blackened steel frame, with eight wrap 24 AWG hand wound coils with resin coating, a 33 μF capacitor, and custom cut springs. This machine has two geometrically different front binding post holes drilled in the side plate making it possible to change this shader to an outliner if so desired. This is a pre-tuned shader that is set up to run at a speed of 100 CPS, at 7.0 volts. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs.

-

A brazed and blackened steel frame, with six wrap 22 AWG, hand wound coils with 1.25”x3/8” steel cores, wrapped with red prism tape, a 22 μF capacitor, and 18 gauge front and rear springs. This is a pre-tuned liner that is set up to run at a speed of 120cps, at 7 volts. This a powerful smooth running liner that has no problem pushing large and small needle groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order by navigating to the custom build section of this website and have one built for your particular needs.

-

A brazed and blackened steel frame, with eight wrap 24 AWG hand wound coils with resin coating, a 33 μF capacitor and custom cut springs. This is a pre-tuned shader that is set up to run at a speed of 90 CPS, at 7.0 volts. If you are looking for a machine similar to this one, but prefer different set up and tuning specifications, you can place a custom order by navigating to the Custom Build section of this site and have a custom machine built to your specifications.

-

A tig welded low carbon steel frame with an oil blackened treatment, 1"x3/8"cores, six wrap 22 AWG hand wound coils, wrapped with burgundy gaff tape. A 22 μF capacitor, and 18 gauge front and back springs. This is a pre-tuned outliner that is set up to run at a speed of 115 CPS, @ 7 volts with a duty of 55% loaded. This machine will push both small and large needle groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs. https://youtu.be/GNsWiAb-R_A

-

A tig welded low carbon steel frame with an oil blackened treatment, 1"x3/8"cores, eight wrap 24 AWG hand wound resin coated coils, A 47 μF capacitor, and 18 gauge front and back springs. This is a pre-tuned shader that is set up to run at a speed of 95 CPS, @ 7 volts with a duty of 50% loaded. This is a strong, hard hitting machine, set up for traditional whip shading. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs. https://youtu.be/GNsWiAb-R_A

-

A brazed brass plated steel frame, with eight wrap 24 AWG hand wound coils with gold prism tape, a 22 μF capacitor and custom cut springs. This is a versatile full size outliner tuned to run at a speed of 100 CPS, at 7.0 volts and still maintain plenty of throw with a good amount of force. Good for running seven liner groupings and smaller. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs.

-

A brazed steel frame with a mint green powder coat, eight wrap 24 AWG hand wound coils wrapped with black prism tape, a 22 μF capacitor, and 18 gauge front and back springs, with a 2" extended nipple speed bar. This is a pre-tuned liner that is set up to run at a speed of 120 CPS, at 6.5 to 7 volts with a duty of 53% loaded. It has a Long stroke and will push all large needle groupings. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs. https://youtu.be/AhObYoIJga0

-

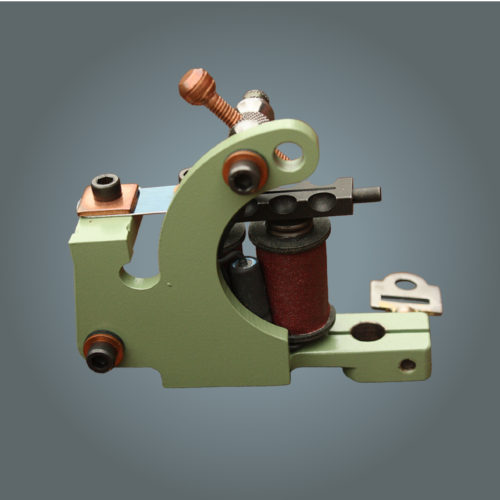

A tig welded steel frame with mint green powder coating, six wrap 22 AWG hand wound coils wrapped with burgundy gaff tape, a 22 μF capacitor, and custom cut springs. This machine has two geometrically different front binding post holes drilled in the side plate making it possible to change this outliner to a shader if so desired. This is a pre-tuned outliner that is set up to run at a speed of 110 CPS, at 7.0 volts. If you are looking for a machine similar to this one, but have different set up and tuning specifications, you can place a custom order and have one built for your particular needs.

Over the last 100 years, the art form of American tattooing has been evolving through the introduction of contemporary modern art and the influences of western culture. Resulting in what seems to be a boundless number of tattoo styles that continue to evoke a desire for personal expression and emotional release, similar to how a beautiful painting commands a viewer’s reaction. In line with the evolution of tattooing, tattoo machines designed to gorgeously engrave colorful inks into skin art, have also evolved with new innovations that allow the professional tattoo artist to create more precisely detailed, and beautiful imagery. Newer tattoo machine frames have been redesigned to be lighter and more comfortable to use. coils and rotary motors have been improved to function for longer hours, and most rotary tattoo machines are almost silent. Professor Incredulous is our premier tattoo machine builder. We custom build and sell pre-assembled tattoo machines designed for professional tattoo artists. We have numerous traditionally styled tattoo machines for sale, each tuned to different specifications. We also repair old professional tattoo machines using original salvageable parts if possible or replacing old ones with new parts. Our objective is to provide professional tattoo artists with exceptional tools, so they can create amazing works of art for their esteemed clientele.

Our pre-assembled professional tattoo machines are pre-tuned to operate the way the machine is described to run, be it a faster or slower running liner, traditional shader, fast or slow black and gray shader, color packer, etc. All of our tattoo machines for sale come with a thirty day money-back satisfaction guarantee, and a lifetime repair warranty. Sorry no tattoo guns

This professional electromagnetic tattoo machine features a ductile iron frame with black oxide treatment, seven wrap 22AWG hand wound coils with 1 1/8″x 3/8″ pure iron cores, wrapped with tan gaff tape, a pure iron A-bar, 22μF capacitor and custom cut springs. This liner runs at a speed of 120CPS, at 7 volts. This is a strong liner with a lot of punch and a long throw, it’s perfect for all liner needle configurations. If you are looking for a coil tattoo machine that is similar to this but prefer a different set up and tuning specs, we can custom build a machine to your specifications.

This professional electromagnetic tattoo machine features a brazed mint green powder coat frame with eight wrap 24AWG hand wound coils with 1.25″x 3/8″ coil cores, wrapped with champagne prism tape, a 47μF capacitor with 18 gauge front and back springs. This gorgeous and versatile color packer is tuned to run at a speed of 110CPS, 7 volts with a duty of 53 loaded. This machine runs smooth with a lot of punch and a nice long stroke for all groupings. If you prefer a different set up and tuning specs, we can custom build a machine to your specifications.

This professional electromagnetic tattoo machine features a brazed and blackened steel frame with eight wrap 24AWG hand wound coils with 1.25″x3/8″ coil cores and resin coating, a 47μF capacitor and custom cut springs. It is a pre-tuned shader that is tuned to run at a speed of 90CPS, 7 volts with a duty of 50 loaded. This machines a traditional whip shader. If you prefer a different set up and tuning specs, we can custom build a machine to your specifications.

One of our newest tattoo machines, it features a tig welded carbon steel frame with an oil blackened treatment, 1”x3/8” cores, six wrap 22AWG hand wound coils, with burgundy gaff tape. The machine has a 22μF capacitor, and 18 gauge front and back springs. This pre-tuned outliner is set up to run at a speed of 115CPS at 7 volts with a duty of 55 loaded. This machine will push both small and large needle groupings.

While we do specialize in providing pre-assembled and custom build professional tattoo machines for sale, we want to provide you the opportunity to build one yourself with our unassembled tattoo machine kits. Our kit comes with all the parts you need in order to build your own tattoo machine from scratch. The kit is limited to a brazed, and blackened frame only. We do offer a choice of frame style and geometry which determines the appropriate coil size, capacitor and armature bar. Our tattoo machine kits come with coils covered with black gaff tape. The shader features eight wrap 24AWG coils, a 47μF capacitor, and a 1.75” armature bar. Our liner includes six wrap 22AWG coils, a 22μF capacitor and a 2” speed bar. All the other parts consist of a pair of brass front and rear binding posts, copper contact screw, all #8×32” socket cap and flat head screws. The kit also includes brass and fiber insulating washers, steel shims, one tube vice screw, two 18 gauge springs front and back, and 6 inches of black wire insulation. You can also specify coil, capacitor and armature bar sizes based on your preferences. Please note that the rear spring will not have a hole punched for the A-bar and the coils and capacitor are not prewired together when you receive them.

Here is what makes us stand out from other tattoo machine builders.

Defiance Manufacturing focuses on quality, not quantity. From the beginning our goal has and will always be to provide reliable tools for professional tattoo artists. This is the reason why we are committed to quality above all else. We want to provide you with professional tattoo machines that you can rely on for consistent daily use. We know that as tattoo artists, reputation plays an integral role in the success of your business. That’s why our sole focus is on providing you with pre-assembled and custom built tattoo machines, that deliver versatile performance results, from the most intricate designs to a big and bold back piece, your clients will see the difference.

All of our custom tattoo machines are built with precision skill, and attention to detail. Our in-house builder Professor Incredulous is relentlessly pursuing the development of new and innovative product features, involving proprietary technology that can elevate your tattooing to the next level. Our Nomi Grip Master System is part of the Tekori line of products that offers unprecedented advancement in the innovation of pigment saturation in the skin.

We only cater to professional tattoo artists, all of our tattoo machines, and equipment for sale are only meant to be used by experienced pros. In order to purchase any equipment from us we shall require verification of your professional status by providing us with proof of any two of the following: a legitimate tattoo shop address, phone number where you are working, website, proof of license and previous customer referral contact information.

Like most machine builders that take pride in the quality of their work, our in-house builder, Prof. Incredulous is extremely meticulous with every machine he builds. We do ask for your understanding and patience when ordering a custom handmade tool such as a professionaly built electromagnetic tattoo machine. There is a process we adhere to in order to ensure quality and consistency in all our products. Rest assured that your patience will be worth the wait, as you can expect to receive a truly consistent and dependable product we hope you will come to enjoy working with and use on a daily basis.

There should be no second-guessing when it comes to the reliability of your tattoo machines. The quality and consistency of the tools used for your tattooing ultimately becomes the benchmark by which your success will be measured in the industry. Never settle for subpar products. We suggest you only use the highest quality tattoo machines available on the market today, and we believe you can rely on the expertise of Defiance Manufacturing’s quality tools to elevate your tattooing to reach your goals. Made by professionals. For professionals.